February 16, 2020

Lower installed cost than precast noise barrier walls

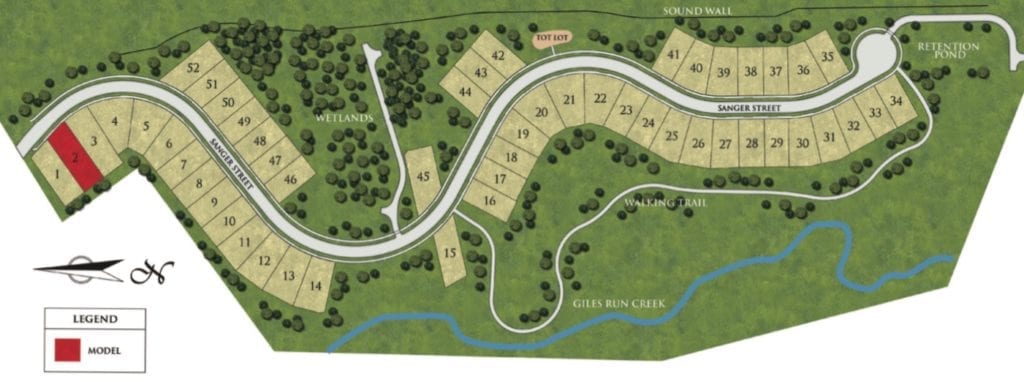

AIL Sound Walls’ latest big project in the Washington, DC area is a 1,752′ Tuf-Barrier (Reflective) noise barrier wall running along the east side of Giles Overlook, a 52-home residential enclave bordering I-95 in Lorton, Virginia.

The layout included multiple angles, grades, heights and foundation types, but our lightweight and nimble PVC sound barrier wall system navigated these complexities with ease — beating competing precast concrete systems on installed cost.

It helped that our system is on a 12′ post spacing, while many precast systems are 20′. We designed a direct-bury foundation for the ground-mounted posts and a flange-mounted attachment for the top of the 260′ cast-in-place concrete retaining wall section.

Owner liked our sound barrier wall system from day one

This project had a long germination period during which we worked with the developer and the acoustical consultant, Hush Acoustics, for a few years before things actually came to fruition. The developer was very keen on our easy-to-install and aesthetically pleasing system from day one, however.

We worked very closely with WG Construction throughout the project, since this was their first time working with our system. We helped them gain approvals from Fairfax County, we expedited production to have the material ready well in advance and we offered on-site support during the install and a final approval meeting.

Positive feedback from WG confirmed that they really valued our thorough support and the simple, lightweight nature of our system.

The sound barrier wall is shown running along the top of this plan of the Giles Overlook development.