Progressive specifiers are choosing lightweight and durable PVC panel

sound wall systems

Sound barrier walls remain an essential part of highway design and construction. Departments of Transportation (DOTs) across the country are looking at new and better materials for them to reduce their overall cost and improve their aesthetics and performance attributes.

First installed in California in the 1970s, early sound barrier walls were larger, hulking concrete or wood structures with minimal aesthetics and long-term performance considerations. Over time, these noise barrier walls offered little sound absorption and degraded with weather.

According to the noise barrier inventory maintained by the Federal Highway Administration, more than 3,000 linear miles of noise wall barriers have been built since the 1970s across the United States. Yet, their cost can be considerable.

For example, between 2014 and 2016, FHWA found that total construction costs for noise barriers topped $671 million in just a three-year period — an average of $2 million per mile of noise wall. That’s why many state DOTs are trying to find ways to reduce the cost of noise-abatement efforts. Progressive specifiers and project partners are opting for lighter-weight, longer-lasting and more cost-effective noise barrier wall solutions like the PVC panel systems from AIL Sound Walls.

Four examples from our Transportation Sound Walls Project Portfolio

Project #1 – Silent Protector noise barrier wall quiets upgraded I-40 in Conway, Arkansas

The I-40 passes through the city of Conway and crosses two of the busiest commuter routes. To alleviate inner city congestion and provide better connections between the highways, the Arkansas Department of Transportation (ARDOT) undertook a substantial upgrade of the I-40 which included road widening and interchange work. As part of this effort, a new highway noise barrier wall was required to protect nearby residents from increased traffic noise along I-40. They chose the Silent Protector system from AIL Sound Walls. Explore this project >

Project #2 – AIL Sound Walls replace older metal sound wall in Worcester, Massachusetts

This was a different project that our installation partner, Premier Fence, brought to us. As part of their maintenance contract with MassDOT, Premier was tasked with replacing a failing galvanized metal sound wall along I-190 at Route 12 in Worcester. Being familiar with our system from several past projects, they recommended AIL Sound Walls. Explore this project >

Project #3 – Bridge-mounted AIL Sound Walls used in Detroit-Downriver Connection

As part of their I-75 Rouge River Project, aka the Detroit-Downriver Connection, the Michigan Department of Transportation (MDOT) needed a half-mile of bridge-mounted noise barrier wall on the southbound I-75. Already familiar with AIL Sound Walls from a successful trial project in Lansing, MDOT chose our innovative lightweight PVC system again for this project. Our engineering team worked with our project partners to tailor the steel post system to mount to the new bridge and meet the schedule demands and MDOT requirements. Explore this project >

Project #4 – Vertical panels lend traditional look to Oakville, Ontario, sound walls

Only 30 minutes from downtown Toronto, the picturesque town of Oakville is one of the most affluent communities in Canada — the perfect setting for AIL Sound Walls to take on a more traditional fence aesthetic with vertical panels along busy Sherwood Heights Drive. Explore this project >

PVC sound barrier walls offer superior design aesthetics

Aesthetic considerations are becoming increasingly important in highway sound barrier walls. AIL Sound Walls are available in Standard or Upgraded Finish levels that offer a variety of color and texture options.

AIL Sound Walls Standard Finish level

Our Standard Finish level provides an economical and attractive sound barrier wall with smooth panels and galvanized steel posts.

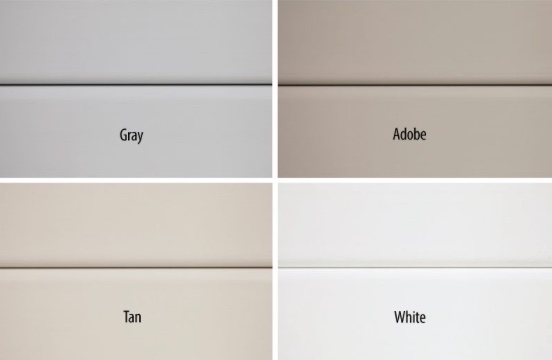

We offer four popular Standard Finish Colors that are designed to enhance any application: Gray, Adobe, Tan and White. Woodgrain texture can be added to any Standard Finish Color as an option. Post sleeves and caps can also be added as an option.

AIL Sound Walls Upgraded Finish level

Our Upgraded Finish Level captures the essence of traditional wood fencing in a durable PVC sound barrier wall.

It features woodgrain colored/textured panels in Green Teak or Honey Maple, accented by post sleeves, caps, top/bottom rails and reinforcement panels in one of our four Standard Finish Level Colors.

AIL Sound Walls are durable and low-maintenance solutions

With their lighter weight, lower installed costs and long-term durability, AIL Sound Walls are a perfect choice to keep the peace in neighborhoods along busy transportation corridors. These sound barriers can be installed easily on narrow roadside job sites and are an efficient land use solution in urban areas. Check out the features and benefits of our lightweight PVC system:

- Impervious to rain, snow and ice and unaffected by de-icing salts

- Will not rust, rot or stain

- Wind load tested for hurricane-force winds

- Meets accelerated test requirements for durability

- Graffiti and tagging resistant

- Designed to meet applicable design codes (AASHTO, IBC, CSA)

- Meets ASTM F3459-21 Standard Specification for PVC Exterior Profiles used for Sound Walls

- See full Product Details, Specifications and Technical Drawings

AIL Sound Walls offer excellent sound-mitigation properties

With Sound Transmission Class (STC) ratings of up to 39, our Silent Protector (Absorptive) and Tuf-Barrier (Reflective) sound barrier systems are engineered for maximum sound reduction of environmental or ambient noise such as highway traffic.

Get flexibility in structure-mounted applications with AIL Sound Walls

For highway noise barriers, AIL Sound Walls are also perfect for narrow roadsides or mounting to bridge parapets, traffic barriers or retaining walls where extra weight is a concern as was done in these project examples on an I-95 bridge in Portsmouth, New Hampshire and along the I-264 in Louisville, Kentucky. The AIL Sound Walls engineering and manufacturing teams are experienced in developing custom attachment hardware for these types of applications.

AIL Sound Walls are a more sustainable and enviro-friendly choice

Noise barrier walls made from concrete, wood or metal have larger carbon footprints than those made from lightweight PVC panels, like AIL Sound Walls. See why PVC is your “greener” choice:

- Made from recycled and recyclable PVC

- Highest percentage of recycled material

- A readily renewable and recyclable product

- Minimized water consumption in manufacturing

- Optimized shipping for reduced CO2 emissions

- Long product lifespan

- Excellent fire-resistant properties

- Smaller footprint, better urban land use

- Earn LEED Points for Green Building

Overall, AIL Sound Walls’ features and benefits quickly stack up

There are many reasons why DOT specifiers and their project partners choose lightweight PVC noise barrier wall solutions from AIL Sound Walls:

- Lightweight PVC construction

- Sound-mitigation performance

- Lower installed costs

- Durable and low-maintenance

- Sustainable and enviro-friendly choice

- Aesthetics and finish levels

- Project design versatility

- Experienced project partner

Learn more about each of the above on our Features & Benefits web page >